Thank you for your feedback. We will contact you soon.

When you need to heat plastic so it can be formed into usable parts, you can’t beat infrared heating. Using IR for thermoforming has many advantages including:

- The ability to precisely control the amount of heat and to target that heat exactly where you want it.

- IR comes up to the proper temperature rapidly and cools down quickly as well, eliminating heat overflow problems.

- IR thermoforming saves energy as a result of the rapid heating and precision targeting.

- Infrared Heaters are widely used on in roll-feed and in-line thermoforming applications

Infrared heaters achieve a high heating efficiency as a result of the correlation between the output wavelength of the infrared heater and the absorption wavelength of many materials. The peak absorption of water is found at 3.0 microns, which falls right in the center of the medium wavelengths. Drying applications require the removal of water. Therefore, it is desirable to correlate the heater output and absorption of water. The peak absorption of most plastics and powder coatings is from 3.5 - 4 microns. The absorption of many materials mirrors the output of infrared heaters. Generating infrared heater energy at the same wavelength as the absorption wavelength of the material maximizes the heat transfer and the process speed. Additionally, it lowers the amount of energy used in the process, thereby reducing the cost per unit part. It should be noted that the goal is not always to correlate the heater output to the absorption of the material. There are many other factors that go into the equation.

The Advantage

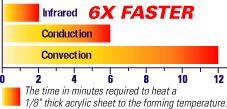

The advantage of infrared heating relates to the high level of achievable heat transfer. That means a faster process, while using less energy. A comparison of different methods might be the heating of a 1/8" thick acrylic sheet.

Heating of the sheet via convection would require 12 minutes to bring the sheet up to the forming temperature. Conduction heating would require 6 minutes to reach the same point. Infrared heating would require only 2 minutes to achieve the same goal.

Infrared can be 6 times quicker at heating the product,

as compared to convection heating.

Basically,thermoforming is the method of heating and molding materials in order to make industrial specific products. It is the most economical and versatile process that is available for manufacturing and packaging other products. However,to attain a uniform thickness of the final item or product with thermoforming is highly intricate. The most commonly used materials is the plastic film or plastic sheets which are measured in a range of different sizes and thicknesses.

Kinetics’ thermoforming heaters are utilized to create the required heat necessary to mold the products. There are many different types of thermoforming heaters on the market,some including convection heater ovens,electrical infrared thermoforming heaters,and gas thermoforming heaters.

Role of Infrared Heating in the process of Thermoforming

One needs to have a better understanding on the working of these heaters. Infrared heaters could have a beneficial and profitable role for thermoformers and other processes that involves high-volume packaging applications. The essence of infrared heating involves important factors categorized into three stages namely:transmission,absorption,and radiation. It is during thermoforming,infrared ceramic heaters are normally mounted on the system reflectors that array upon a platen – a part of a production line.

In the category of types of thermoforming heaters,Kinetics’ single heater is equipped to form a plastic as thick as 0.48 cm,whereas,on the other hand,our double heaters are operated entirely with the help of electricity and also have an enclosed heater area in their systems.

Specifications

All our thermoforming heaters have a control wiring of 110 volts and up to 15 pre-programmed sequences. The overall system movements of these heaters are powered by hydraulics in order to ensure a powerful and smooth process. For further details,contact Kinetics at (973) 575-5332.

Solder reflow requires strict temperature control to get the needed tight joining. Infrared heat is ideal for the reflow process because:

- IR allows you to target exactly the area you want the solder reflow to occur.

- Infrared heat also offers the advantage of being essentially instant on and instant off, saving energy.

- Infrared solder reflow can be performed in an oven that allows multiple zones individually controlled for temperature.

- With IR, solder reflow is fast, as much as six time faster than other kinds of heat.